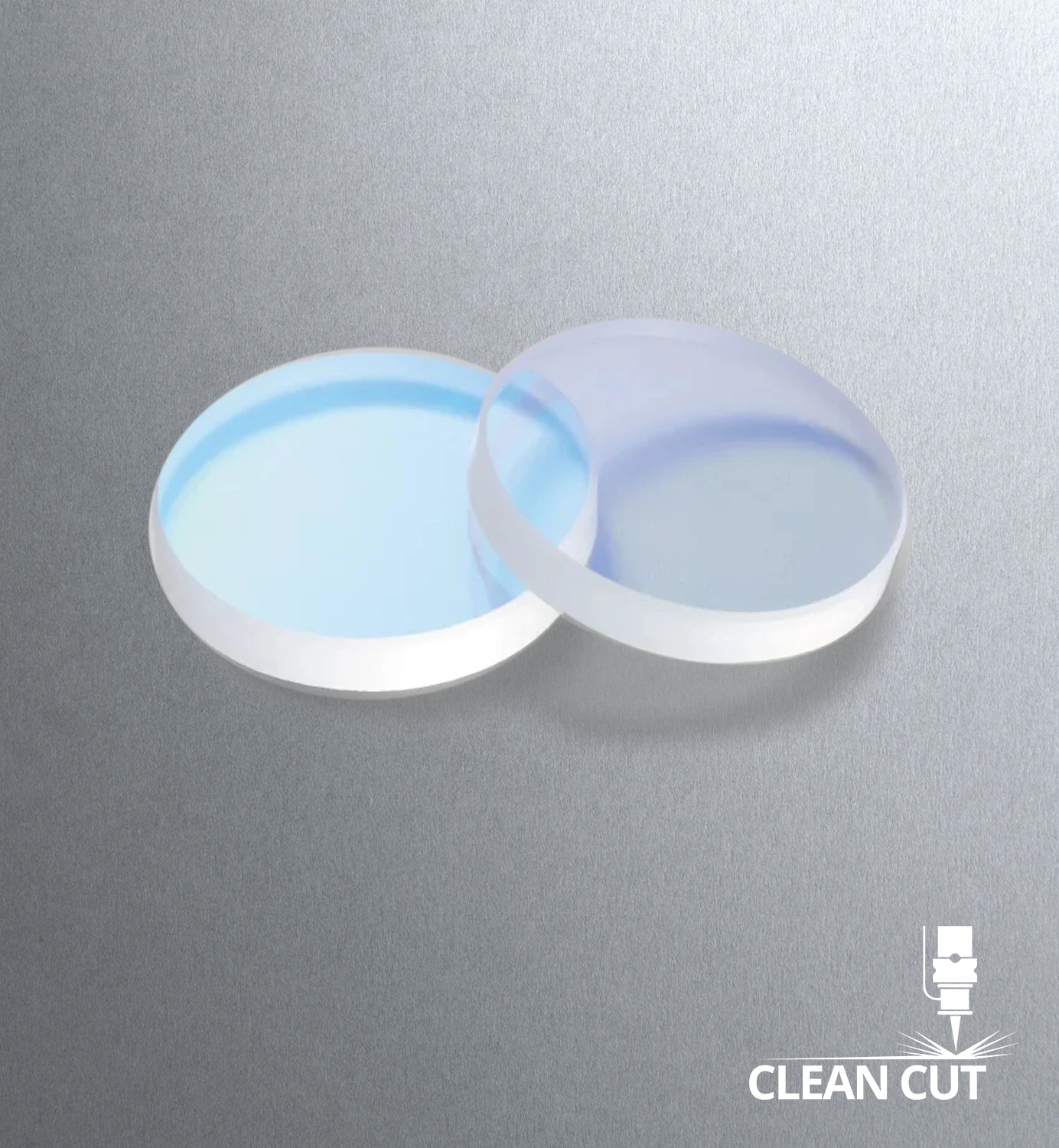

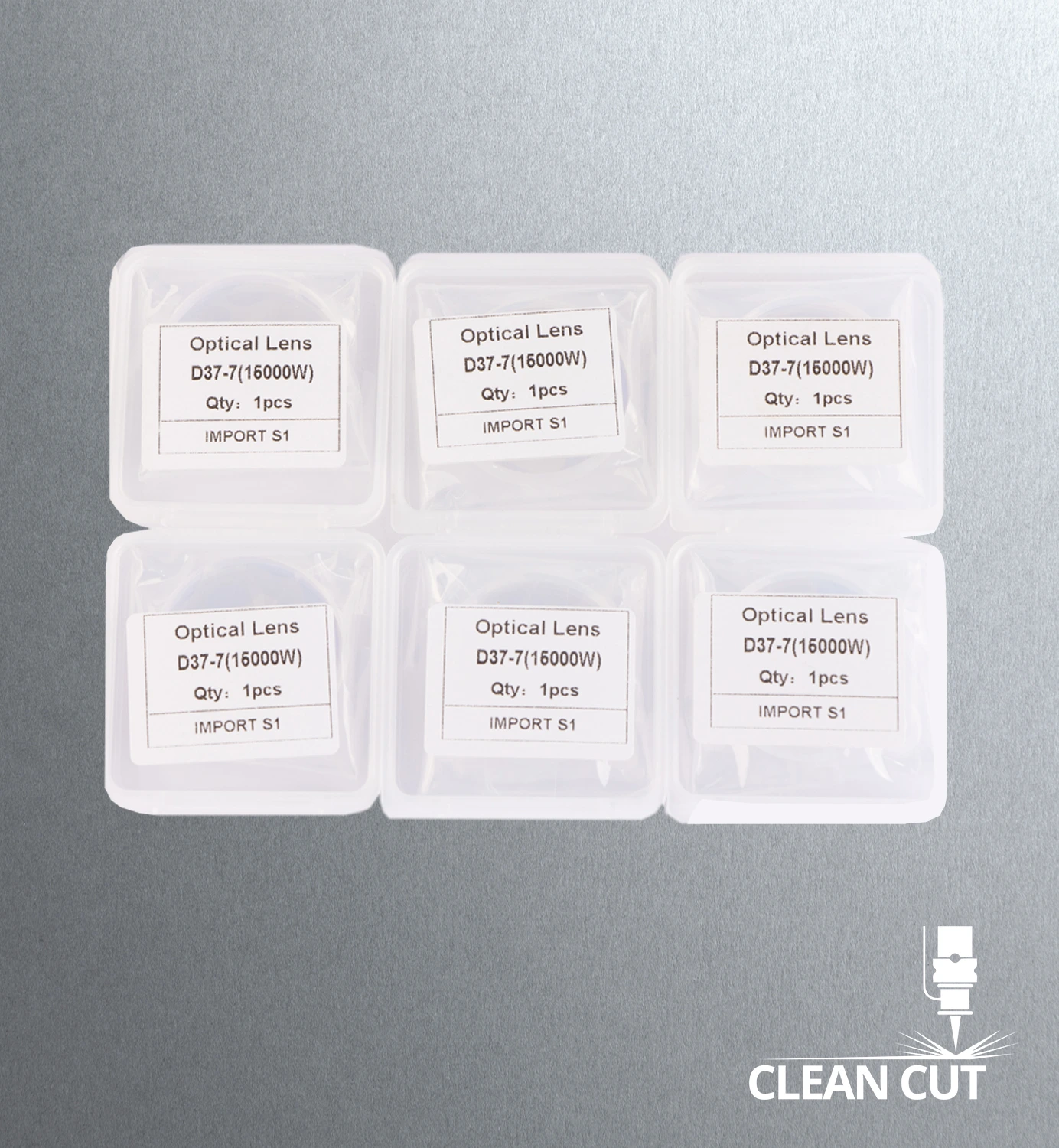

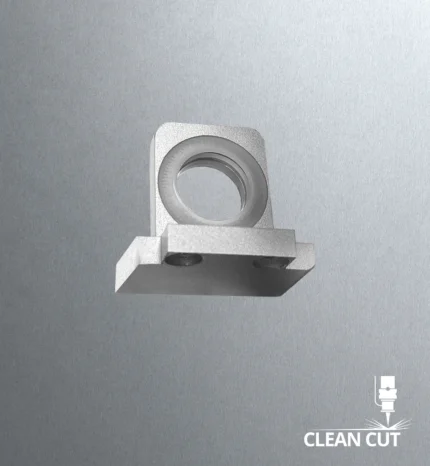

RAYTOOLS Protective window 37×7

| brand | |

|---|---|

| size of the protective glass | |

| product manufacturer | |

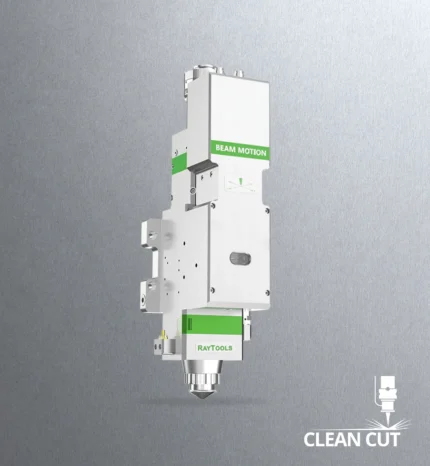

| suitable for cutting head |

BM06K ,BS06K |

Description

Technical Specifications of Protective Glass 37 x 7 (RAYTOOLS)

- Dimensions: 37 x 7 mm

- Usage: Designed for lower holder

- Compatible with Cutting Heads: BM06K, BS06K

- Power Capacity: Suitable for use up to 12 kW

- Material: Constructed from durable materials for industrial environments

- Laser Beam Transmission: Provides precise laser beam transmission

- Protection: Safeguards other optical components from splatter

- Efficiency: Enhances energy transmission and reduces laser reflection

- Installation: Easy installation with quick and secure replacement

Other Description

Fiber laser cutting machine protective glass has specific technical features designed to safeguard internal components, particularly focus lens. These protective glasses typically have the following characteristics:

- High Resistance to Heat and Laser Radiation: Protective glass must withstand the high heat intensity generated by the laser beam while maintaining transparency for precise beam transmission.

- Glass Thickness and Diameter: The thickness and diameter of the protective glass vary depending on the machine type. However, it must be designed to resist pressures and impacts from cutting operations, protecting lenses and other sensitive components.

- High Optical Clarity and Transparency: These glasses must offer high transparency to avoid any degradation in laser beam quality, preserving cutting accuracy.

- Durability and Longevity: Protective glasses are made from high-quality materials to resist splatter from molten materials and dust, reducing the need for frequent replacements.

Selecting high-quality protective glass is essential to extend the machine’s lifespan and reduce maintenance and repair costs.