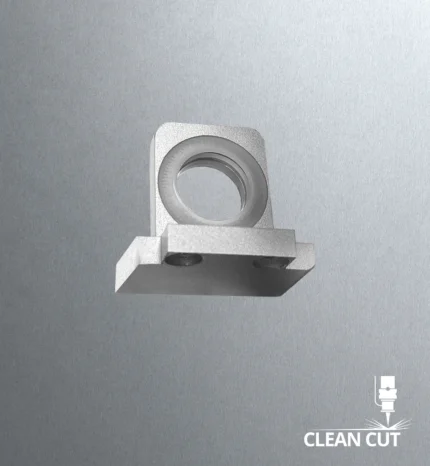

Welding protective glass 18×2

| size of the protective glass |

|---|

Description

Technical Specifications of welding Protective Glass (up to 3 kW)

- Power Capacity: Suitable for use up to 3 kW

- Material: Constructed from durable materials to withstand industrial environments

- Laser Beam Transmission: Ensures precise laser beam transmission

- Protection: Shields other optical components from splatter

- Efficiency: Enhances energy transmission and reduces laser reflection

- Installation: Easy installation with quick and secure replacement

Other features

1. High resistance to heat and laser beam: protective glasses must be able to withstand the high intensity of heat produced by the laser beam and at the same time maintain their transparency for the accurate passage of the beam.

2. Thickness and diameter of the glass: The thickness and diameter of the protective glass varies depending on the type of device, but it must be designed in such a way that it can withstand the pressures and blows caused by the cutting operation and protect the lenses and other sensitive components.

3. Transparency and high optical quality: These glasses must have high transparency so as not to cause any loss of quality in the passage of the laser beam and maintain the cutting accuracy.

4. Durability and longevity: protective glasses are made of high quality materials to resist the splash of molten materials and dust and do not need to be replaced frequently.

Choosing high-quality protective glass is essential to increase the life of the device and reduce maintenance costs